Set Up Boxes

A folding carton is a packaging solution that is cut, folded, and glued to create a three-dimensional structure. It is a versatile and cost-effective option for packaging various goods, from food and beverages to cosmetics and consumer electronics. This type of packaging is used extensively in the retail industry, protecting products during transportation and storage while contributing to brand marketing.

Deluxe Packaging has been a leading provider of premium packaging products, including folding cartons and corrugated boxes, since 1982. Our team will develop and deliver an excellent product packaging solution regardless of your application or industry.

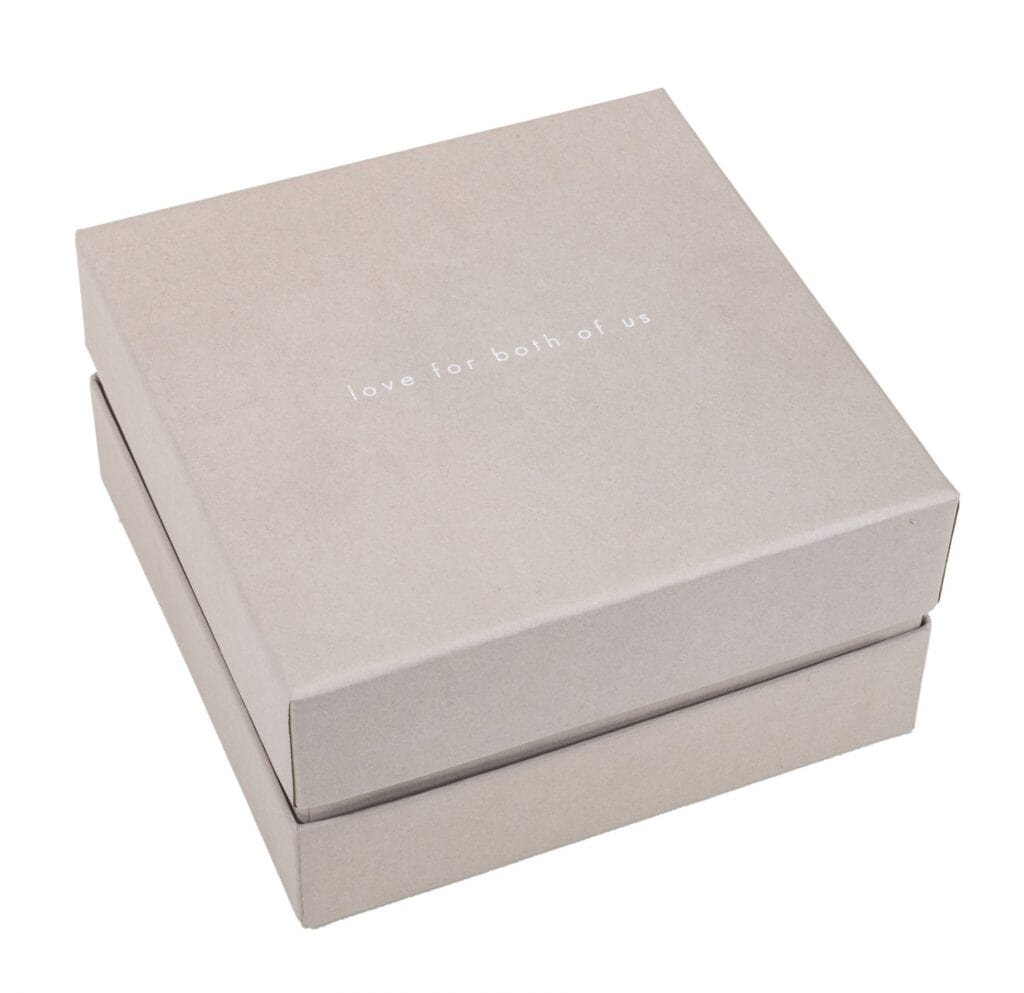

Set-Up Boxes are called “rigid” boxes for a reason. They’re strong, durable and non-collapsible, offering protection for your products. This box style lends itself well when extra protection is needed; for example with candles, medical supplies, glassware, and candy to name a few.

A Set-Up Box lets your customer know that something special is inside, and assures them they are buying a quality product. Because of their durability and elegance, customers often keep, save and re-use them. When your company logo or name is printed or foil stamped on the exterior, it increases the time in which your customers, and others, see it. For this reason, they are an excellent marketing tool.

Graphics

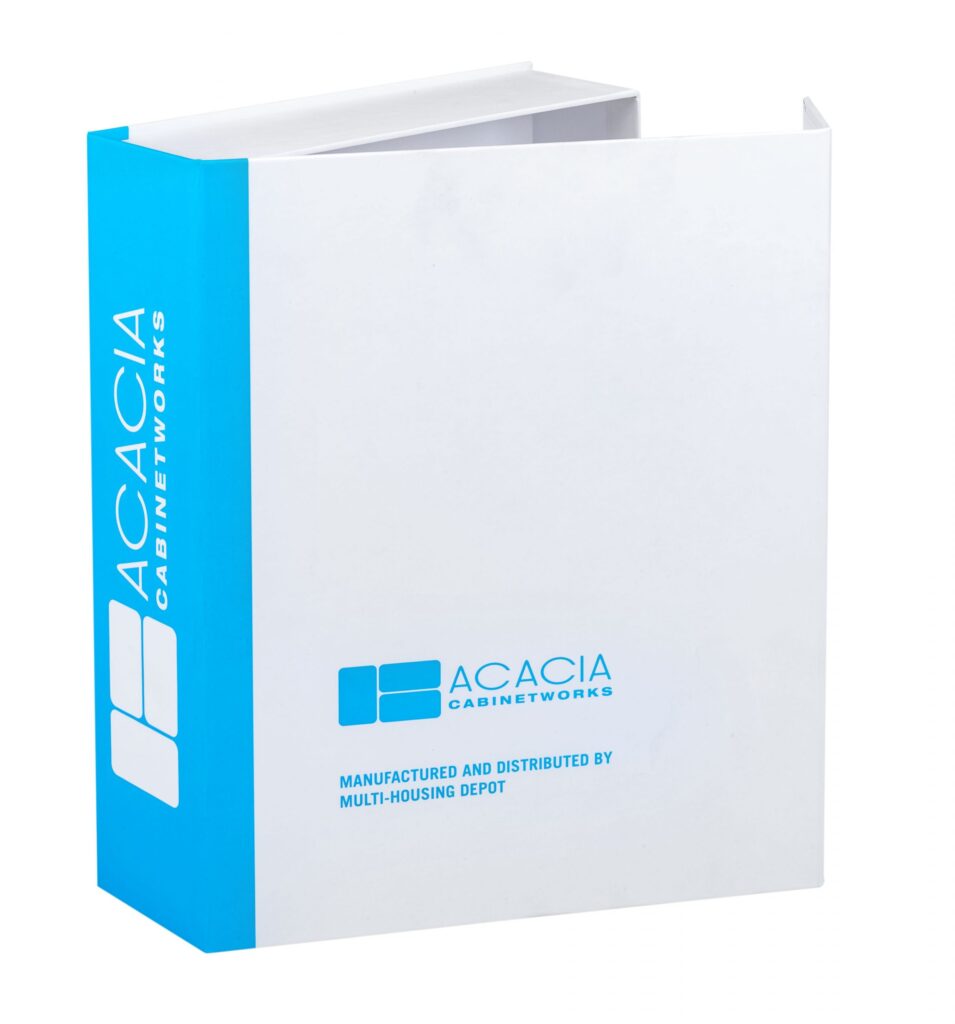

Don’t be afraid to splurge on graphics. It’s what sets your box apart from your competitor’s. When done right, graphics offer brand recognition, so that your customers immediately recognize your name and logo, and therefore, your products. No logo? Ask about Deluxe Packaging Company’s graphic design services.

Whether you choose to say it simply or scream it boldly, graphics are your opportunity to communicate with the customer. Graphics tell your customer who you are, what’s inside, how to use it, and sometimes, even when to throw it away. Your graphics can be as simple as a one-color line logo or as complex as a four-color photographic image. Foil stamping, hot stamping, and embossing are also available. Varnish, aqueous coating, UV coating, and film lamination can be added when needed or desired. You can supply your Deluxe Packaging representative with a digital copy of your artwork (less than 3.4 mega pixels is not recommended), or ask them about our affordable graphic design service.

Offset Lithography Printing

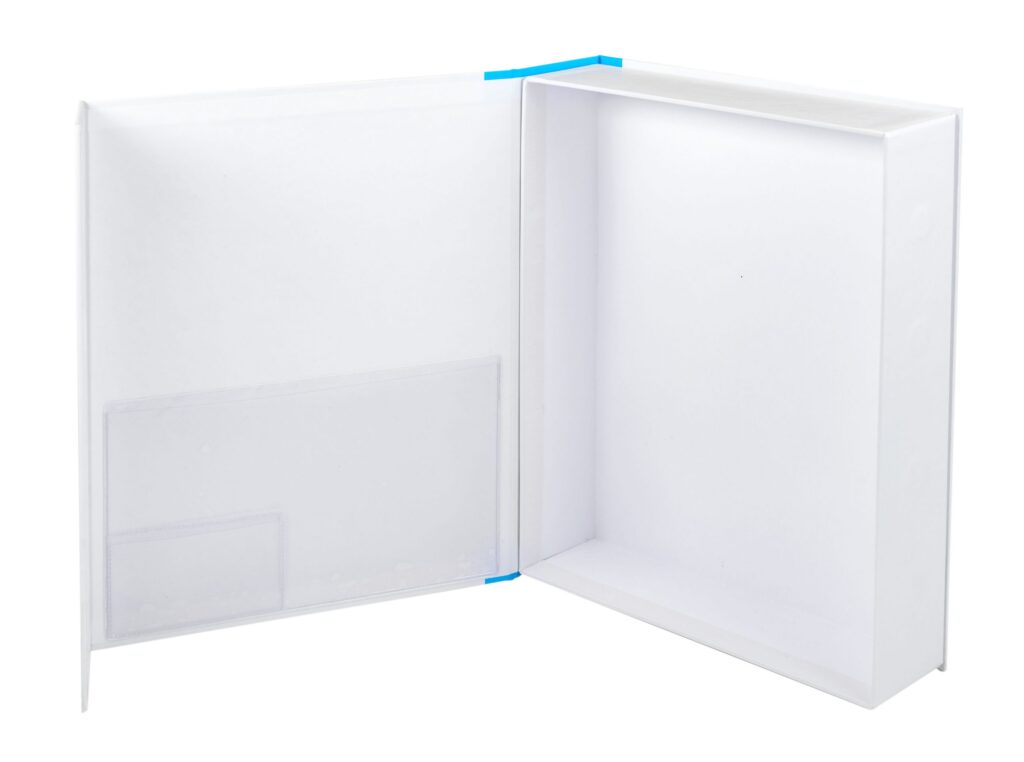

Add graphics to your set-up box with conventional printing. One- or two-color line art on white or colored paper is the most cost effective. However, the rich four-color photographic images on your set-up box really catch the consumer’s eye. You can print just the top of the lid or flood the entire lid and base. Looking for a cost effective way to get your four-color photographic image? Print the entire telescope lid, and leave the base white.

Foil Stamping/Hot Stamping

Both foil stamping and hot stamping are cost effective ways to say what you want to say and say it with distinction. Stamping has its own unique look that printing cannot emulate. Stamping also adds flare for high-end products. Choose foils for a vibrant, sophisticated look. Choose non foils for a softer, more subtle style.

Embossing

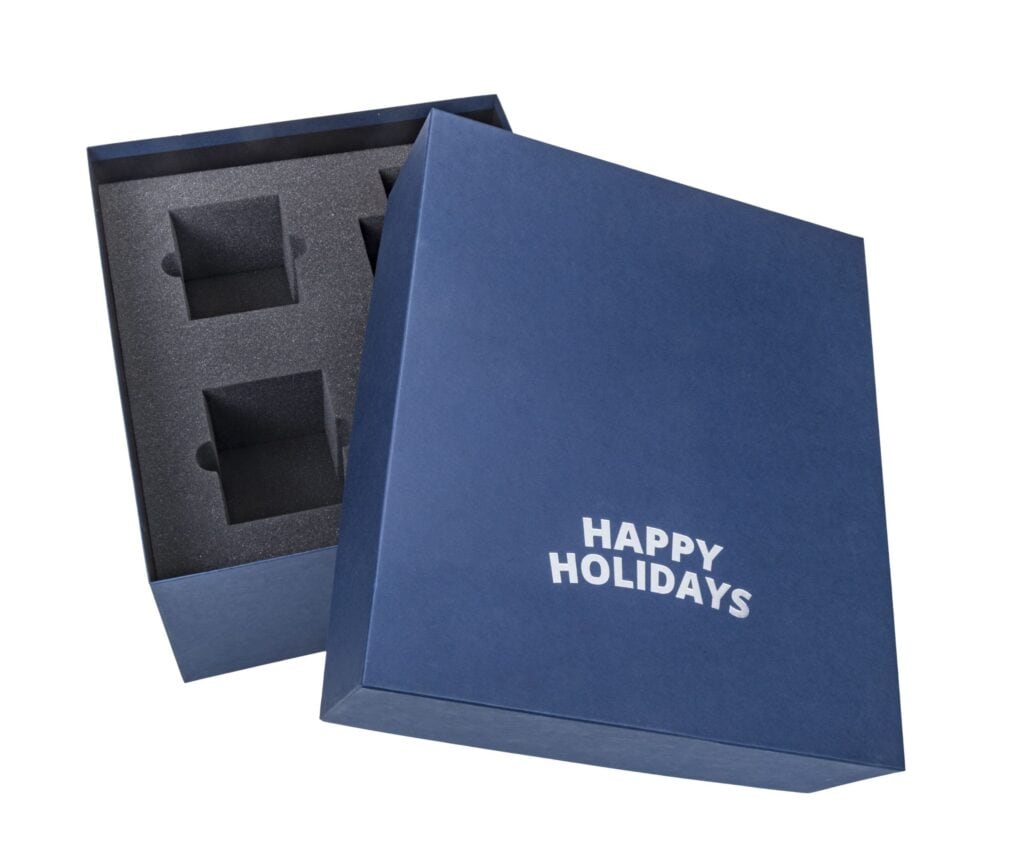

The art of embossing has been around for hundreds of years without showing any signs of extinction. Throughout the years, mankind has embossed many surfaces such as jewelry and metals, book covers, and legal documents, invitations and stationery. For an elegant, and timeless look, let Deluxe Packaging raise your graphics through embossing. Embossed patterns can then be foil stamped or left “blind”, the term for embossing patterns that are left unstamped and uncolored. Embossing signals your customers that something stylish is just under the lid.

Coatings

Coatings not only make the graphics look better, they offer a layer of protection so you don’t have to worry about ink fading or smearing when the boxes are frequently handled. Choices of coatings include Varnish, Aqueous, UV, and Film Lamination. For most one- and two-color line logos, varnish offers enough protection to prevent smudging. Heavier print coverage can usually be protected by aqueous coating which is a harder coating that also adds a nice sheen to your graphics. UV coating provides the best protection, and really makes your graphics pop with a shine comparable to glass or acrylic.

What Are Rigid Set-Up Boxes?

Rigid set-up boxes are highly durable box packages built from sturdy materials, such as cardboard, paperboard, chipboard, and rigid foam. Unlike other types of bags or folding cartons, rigid set-up boxes are designed to stand on their own and be assembled without additional glue or tape. They usually protect luxury, fragile items and provide a memorable unboxing experience.

Custom rigid boxes can be designed with brand logos and other graphics or text that lend a polished, professional image to your brand. The high-quality, durable packaging signals to consumers that the product inside is of similarly high quality. Using the right combination of printing, foil stamping, embossing, and coatings will help your product stand out among its competitors.

We’ll explore more of the benefits custom rigid boxes provide for consumer product brands, as well as their most common applications, materials used, and other considerations to make when selecting this luxury packaging solution.

Benefits of Rigid Set-Up Boxes

Rigid set-up boxes offer the protection and durability customers expect when purchasing high-end and/or fragile products. Luxury rigid boxes offer protection with style, providing an attractive way of ensuring the packaging—and the items inside—withstand rough handling during transit.

When shipping items such as jewelry, cosmetics, or other high-end products, durability and image are essential. Custom rigid boxes also provide a crucial way for brands to present their brand with authority, making rigid set-up boxes a must-have in any high-end product marketing campaign. The benefits of rigid set-up boxes include:

- Durability of the packaging and product protection

- Elevated brand image

- Improving the product’s perceived value

- Nearly unlimited custom branding options, such as hot stamping or embossing

With the finest high-end boxes, the packaging itself becomes something of a product. End consumers often reuse set-up boxes to store their own belongings, searing brand recognition deeper into your audience’s awareness. Merchants also find value in reusing rigid boxes, such as for new products, return shipments, and shelf displays. However they are used, rigid set-up boxes serve as a striking demonstration of the care your company puts into its products and brand.

Another benefit is that set-up box packaging materials and designs are very easy to assemble. They fold into their final shape without requiring any other materials (e.g. adhesives, staples, glue). Some types can be easily stored in a flat, pre-formed state, then constructed into a usable form as needed. Because rigid set-up boxes enhance protection for your products, they reduce the likelihood of damaged products and subsequent returns or replacements.

Common Use Cases for Rigid Set-Up Boxes

Companies rely on rigid set-up boxes to present premium products as professionally and memorably as possible. The most common types of products rigid boxes package and protect include:

- Luxury/premium products, such as jewelry, fragrances, designer cosmetics, art, or any fragile item

- Gifts and special items

- High-end retail products, including smartphones, computers, appliances, and other electronics

Whether a retailer wishes to convey a feeling of exclusivity and quality, protect their products more effectively, or some combination of the two, rigid set-up box packaging is an ideal solution.

Materials Used For Rigid Set-Up Boxes

For standard or custom rigid boxes, fulfilling the purposes listed above requires thoughtful design according to the intended use case. In addition to the rigid set-up box’s shape and form, the primary factor to consider is how it is constructed. Different rigid box packaging materials can be made from a wide range of materials, which all come with their own properties, costs, and design possibilities.

The most frequently used materials for rigid boxes include:

- Chipboard: Made from recycled paper fibers, chipboard is a thick paper material made from wood chips and a resin binder. The typical thickness of chipboard in rigid set-up boxes is 2 to 3 mm.

- Paperboard and cardboard: Rigid set-up boxes use thick paperboard or cardboard to form solid, rigid packaging, in contrast to flexible packaging, which can change shape. Rigid paperboard boxes usually consist of gray Kraft boards covered with wrapping paper, glued to the outside of the box.

- Corrugated cardboard: Corrugated cardboard consists of a fluted sheet sandwiched between two flat linerboards. This material can be used as the rigid box packaging itself or as protective inserts.

- Plastic and other non-paper materials: Rigid set-up boxes and their inserts can be made of plastic. Other non-paper materials include molded pulp or stiff foam.

The desired appearance and function of the rigid set-up box determines the type of materials used. Most high-end rigid boxes are designed with unique finishes that influence texture, color, and enclosure mechanisms.

For instance, using small magnet closures that keep the box securely shut but easily open is a popular trend in packaging for cell phones and other electronics. Graphic design considerations, such as foil stamping and embossing, create various finishes on the rigid box. Color, ink, coatings, and desired texture are just some of the considerations.

The shape of the rigid box further impacts which materials are used. Multiple layers of flexible paperboard, for instance, can create rounded edges or tubes, which are popular for items such as health and beauty products. Corrugated board is particularly useful for allowing more control over the angles of the set-up box.

Rigid Set-Up Boxes By Deluxe Packaging

Premium luxury goods, fragile items, or any product needing a more polished presentation benefit from rigid set-up box packaging. Custom rigid boxes elevate brand image, giving customers a sense that your company is an authority in your market.

Whether it’s for gift giving, improved marketing, or ensuring maximum protection, rigid set-up boxes are an important part of your marketing efforts and overall brand. For over 40 years, Deluxe Packaging has partnered with customers across numerous industries to deliver custom packaging to exact specifications. To demonstrate our customer-first approach, 100% of our products are recyclable. In addition to rigid set-up boxes, our solutions include:

- Honeycomb packaging

- Point-of-purchase (POP) displays

- Fiberboard and corrugated tubes

- Folding cartons

- Custom cases

- Molded pulp

- Corrugated plastic

Contact us today to learn more about our set-up boxes and other capabilities.